This system would use the same underlying technology as 3DM Analyst Mine Mapping Suite to construct an automated truck volume measurement system.

It would measure the volume of material carried on the back of trucks, train carriages, barges or any other container.

Figure 1. Truck with a load of ore

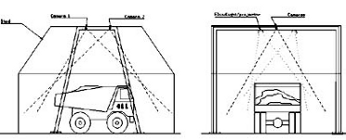

Figure 2. Gantry with cameras

The fully loaded truck would drive underneath a gantry when leaving the pit, without slowing down. The system would then automatically activate as the truck approached and sense the identification signal from the truck.

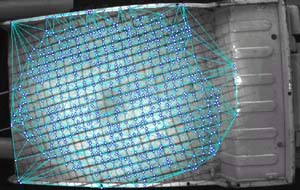

Figure 3. Image of truck and DTM

Images of the load on the tray back would then be taken using digital cameras and then analysed by the software to establish a reference frame and generate a surface model. The volume would then be calculated by comparing the surface model with the stored tray surface model for that particular truck.

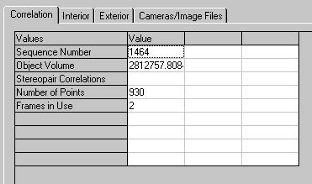

Figure 4. Volume display

The truck identification number, date, time and volume would then be recorded and optionally sent to the mine office.