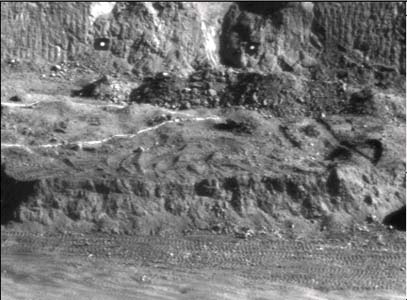

Figure 1. Image of the section of the pit to be surveyed |

This system was developed to provide accurate production figures on a hourly basis. The earth moving contractor was paid for the volume of material removed from an open cut mine. Usually the volume mined is established by a traditional survey of the pit on a monthly basis. Our client wanted much more frequent updates of the production figures in order to evaluate the efficiencies of equipment and shifts, etc. |

|

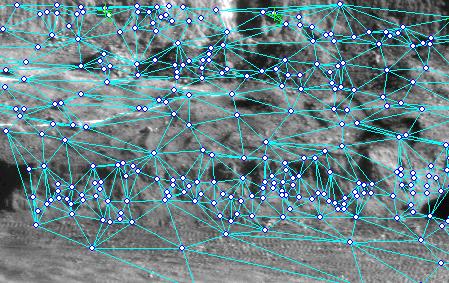

| Figure 2. Display of computed 3D points and DTM triangles |

This was the first system ever built on the 3DM technology, back in 1997. The system used a minimum of 4 control points to determine the exterior orientations of the cameras. The pit had a diameter of approximately 250 m and a depth of 30 m. Two CCD cameras were set up on the opposite rim of the pit. This allowed an area of approximately 50m x 50m to be surveyed. The system computed a digital terrain model (DTM) of some 600 points every 3 minutes. It also computed and displayed the volume of material removed from the test area.

Further developments in the 3DM technology have led to improved image matching and centroiding software being included.